We are experienced manufacturer. Wining the majority from the crucial certifications of its market for

Shell Panels 5.8kg - Gun Carry Case

,

Australian Soundproof Sliding Window

,

Aluminum Corrugated Composite Panel

, We've been willing to provide you with the lowest selling price during the market place, greatest high quality and quite nice sales service.Welcome to do bussines with us,let's be double win.

Excellent quality Fire Proof Aluminum Composite Panel -

Stone Finish Aluminum Solid Panel – Altop Detail:

The aluminum-plastic composite panel (APCP) consists of thirteen layers materials. The aluminum plate is made of high quality alloy aluminum and the core

materials are polyethylene and modified polyethylene. The two layers aluminum plate and one layer core material form a sandwich structure to bear strength for

the composite plate with the characteristics of lightness, intensity and firmness. After chemical processing, the two surfaces of the aluminum plate is attached

with a layer of hard and uniform chemical conversion coating with the thickness between 5μm and 7μm to reinforce anti-corrosion function for the aluminum material and promote interface bonding force for the aluminum plate with other materials. The polyethylene is a kind of material which is hard to be bonded due to its low surface tension; it should be firmly bonded with the aluminum plate depending on the physical and chemical actions generated by the macromolecule transition layer instead of being directly bonded with the aluminum plate.

The thickness of PVDF fluorocarbon coating on the decorative surface should be more than 25μm.The coating property of decorative surface conforms to the code of America Architecture Manufacturing Association (AAMA) and other relevant architecture aluminum product coating codes and standards. The coating color may be selected according to the standard color card of the company or specified by the customer. A layer of black and white protective film is covered on the decorative surface of the aluminum-plastic composite panel to prevent coating damage

during plate transportation, processing or installation.

Main applications fielding: In addition to curtain wall, interior and exterior walls, foyers, restaurants, shops, conference rooms and other decoration, can also be used for the renovation of old buildings, counters, surface of furniture, surface for vehicles.

Product Features:

Light weight, good rigidity, rich colors catalogues, easy for decorating

Good surface smothing and good time durability, easy for processing;

Fire resistance, strong acid resistance, good sound insulation capability;

Easy to maintenance, easy to clean, etc.

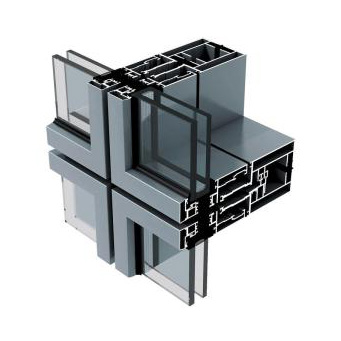

Product detail pictures:

Related Product Guide:

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of

Excellent quality Fire Proof Aluminum Composite Panel -

Stone Finish Aluminum Solid Panel – Altop, The product will supply to all over the world, such as: Paraguay

, Kazakhstan

, Mauritania

, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

By Jane

from Philippines

- 2017.01.11 17:15

By Jane

from Philippines

- 2017.01.11 17:15

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.

By Honorio

from Detroit

- 2017.09.29 11:19

By Honorio

from Detroit

- 2017.09.29 11:19