Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for

Flourocarbon Painting Aluminum Veneer

,

Panels

,

Arced connections

, We welcome all of the purchasers and pals to contact us for mutual added benefits. Hope to do additional business enterprise along with you.

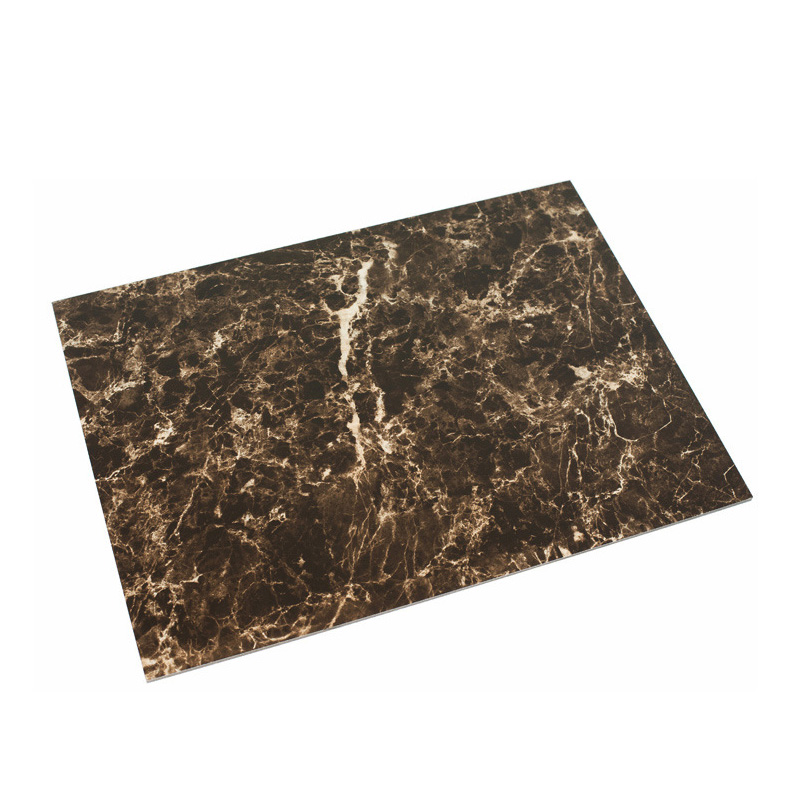

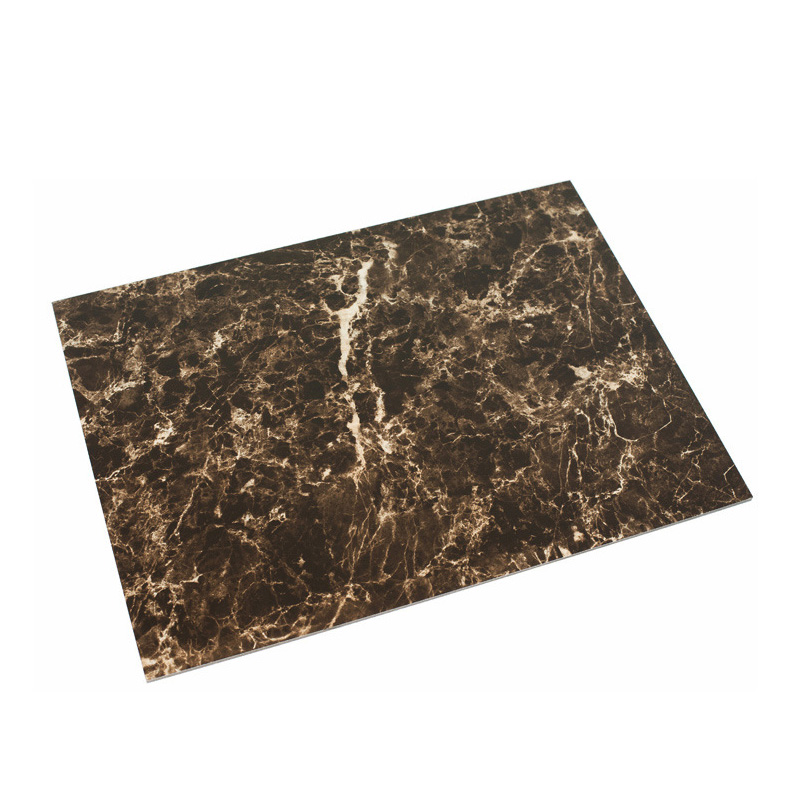

Manufacturing Companies for Aluminum Honeycomb Panel -

Stone Finish Aluminum Solid Panel5 – Altop Detail:

The aluminum-plastic composite panel (APCP) consists of thirteen layers materials. The aluminum plate is made of high quality alloy aluminum and the core

materials are polyethylene and modified polyethylene. The two layers aluminum plate and one layer core material form a sandwich structure to bear strength for

the composite plate with the characteristics of lightness, intensity and firmness. After chemical processing, the two surfaces of the aluminum plate is attached

with a layer of hard and uniform chemical conversion coating with the thickness between 5μm and 7μm to reinforce anti-corrosion function for the aluminum material and promote interface bonding force for the aluminum plate with other materials. The polyethylene is a kind of material which is hard to be bonded due to its low surface tension; it should be firmly bonded with the aluminum plate depending on the physical and chemical actions generated by the macromolecule transition layer instead of being directly bonded with the aluminum plate.

The thickness of PVDF fluorocarbon coating on the decorative surface should be more than 25μm.The coating property of decorative surface conforms to the code of America Architecture Manufacturing Association (AAMA) and other relevant architecture aluminum product coating codes and standards. The coating color may be selected according to the standard color card of the company or specified by the customer. A layer of black and white protective film is covered on the decorative surface of the aluminum-plastic composite panel to prevent coating damage

during plate transportation, processing or installation.

Main applications fielding: In addition to curtain wall, interior and exterior walls, foyers, restaurants, shops, conference rooms and other decoration, can also be used for the renovation of old buildings, counters, surface of furniture, surface for vehicles.

Product Features:

Light weight, good rigidity, rich colors catalogues, easy for decorating

Good surface smothing and good time durability, easy for processing;

Fire resistance, strong acid resistance, good sound insulation capability;

Easy to maintenance, easy to clean, etc.

Product detail pictures:

Related Product Guide:

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for

Manufacturing Companies for Aluminum Honeycomb Panel -

Stone Finish Aluminum Solid Panel5 – Altop, The product will supply to all over the world, such as: Suriname

, Barcelona

, Maldives

, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

By Arabela

from moldova

- 2018.10.01 14:14

By Arabela

from moldova

- 2018.10.01 14:14

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

By Philipppa

from Grenada

- 2017.09.30 16:36

By Philipppa

from Grenada

- 2017.09.30 16:36